Durable Prints. Scalable Production. Reliable Results.

Screen Printing Techniques & Applications

Explore the various screen printing methods and how to use them effectively. Explore each option below to learn more about the process, best practices, and ideal products for each technique.

Plastisol ink is the industry standard for screen printing, known for its durability, versatility, and bold color vibrancy. Unlike water-based inks, plastisol sits on top of the fabric fibers rather than soaking in, creating an opaque, slightly raised print that holds detail exceptionally well. It cures at high temperatures, bonding permanently to the garment for a print that withstands repeated washing and heavy wear without fading or cracking.

Because it offers excellent opacity on dark fabrics and can be mixed to match any Pantone color, plastisol is the preferred choice for bold graphics, athletic wear, and high-volume production runs. It can also be modified with additives to achieve specialty effects such as soft-hand finishes, high-density textures, or puff effects, making it one of the most versatile tools in apparel decoration.

Simulated process printing is a high-end screen printing technique that recreates full-color, photographic-style artwork using spot colors and halftones instead of traditional CMYK inks. By carefully blending a custom mix of opaque plastisol inks, it achieves vibrant tones, smooth gradients, and detailed images—even on dark garments where standard process printing falls short.

This method is ideal for complex graphics, detailed illustrations, and photorealistic designs that demand maximum color accuracy and impact. Simulated process delivers the richness of digital imagery with the durability, brightness, and texture of traditional screen printing, making it the go-to choice for brands that want their artwork to truly stand out.

6-Color Grayscale Simulated Process Printing is an advanced screen printing method that uses a carefully balanced set of six inks to reproduce detailed images, gradients, and photographic effects in black-and-white or grayscale. By layering halftones of varying density, this technique captures depth, highlights, and shadow detail with impressive clarity—while keeping ink counts efficient and production scalable.

Ideal for high-volume runs of detailed artwork, photographic portraits, or tonal designs, 6-Color Grayscale Sim Process delivers the look of a full photographic print while maintaining the durability and texture of traditional screen printing. The result is a striking, high-contrast decoration with a smooth tonal range that feels both modern and timeless.

CMYK process printing uses four transparent inks—cyan, magenta, yellow, and black—to recreate full-color images through halftone blending. This technique is excellent for photorealistic artwork, gradients, and detailed imagery, delivering a smooth, magazine-style finish.

However, CMYK has some important limitations. It performs best on white or very light-colored shirts, since the inks are transparent and cannot achieve strong opacity on darker fabrics. Additionally, because CMYK relies on precise ink balance, it is not always ideal for large-scale production runs; even slight shifts in ink density or screen alignment can cause color drift, leading to inconsistencies across prints.

For consistent, high-volume production on a wider variety of garments, simulated process printing is often the better choice.

3D Puff Screen Printing is a specialty decoration technique that adds raised, textured dimension to your designs. Using a heat-reactive puff additive mixed into screen printing ink, the artwork expands during the curing process, creating a bold, three-dimensional effect. This process delivers a unique, tactile finish that makes logos, graphics, and text stand out with depth and visual impact.

A tonal imprint creates a subtle, understated decoration by printing a design in a color that closely matches the garment itself. Instead of bold contrast, the artwork blends with the fabric to produce a sleek, monochromatic effect that catches the light and shifts in visibility depending on angle and movement. This technique delivers a refined, fashion-forward look that works especially well for premium apparel, lifestyle brands, and corporate wear where a more sophisticated, minimal aesthetic is desired.

The distressed artwork texture effect is designed to give prints an authentic, worn-in look. By intentionally breaking up the artwork with cracks, chips, and weathered details, the design appears aged as if it has been naturally faded and cracked over years of wear. When applied to screen printing, embroidery, or digital transfers,

Vintage or washed printing effects are achieved by combining soft-hand inks—such as water-based or specially reduced plastisol—with garments made from soft, textured fabrics. The semi-transparent nature of these inks allows the fabric’s natural character to show through, resulting in a worn-in, retro look that feels both authentic and timeless.

Glitter ink is a specialty screen printing ink designed to add sparkle, shine, and eye-catching texture to apparel. Made by suspending metallic or polyester glitter flakes in a clear or colored plastisol base, this ink creates a bold reflective effect that shimmers under light. The result is a decoration that instantly stands out, perfect for fashion lines, spirit wear, promotional merchandise, and statement designs.

Glitter ink is both durable and versatile, available in a wide range of colors and flake sizes to achieve subtle sparkle or dramatic shine. It prints well on dark garments and can be combined with other specialty inks to create layered, multi-dimensional effects. For brands seeking a high-impact, glamorous finish, glitter ink delivers unmatched visual appeal.

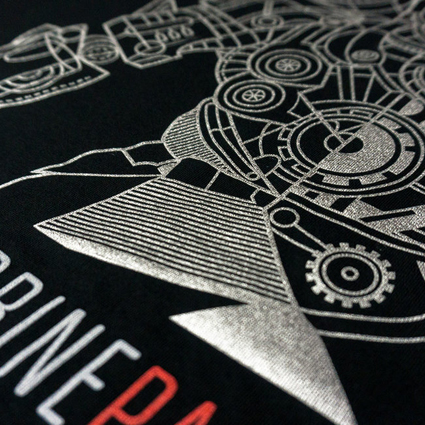

Metallic ink is a specialty screen printing ink formulated with fine metallic flakes that create a smooth, reflective finish. Unlike glitter, which produces a textured sparkle, metallic ink delivers a sleek, polished sheen that mimics the look of metals such as gold, silver, bronze, or copper. This effect gives prints a premium, high-end appearance while maintaining the durability and flexibility of plastisol-based inks.

Metallic inks are ideal for logos, lettering, and accent details that need to stand out with a touch of sophistication. They work especially well on darker garments, where the contrast enhances the reflective effect. For brands and distributors looking to add luxury, elegance, or bold style to their apparel, metallic ink provides a long-lasting decoration with striking visual impact.

Neon (fluorescent) inks are high-visibility specialty inks formulated to produce ultra-bright, glowing colors that demand attention. These inks use fluorescent pigments that react vividly under natural light and intensify under blacklight, making them perfect for streetwear, athletic apparel, concerts, events, and promotional gear.

Unlike standard inks, neon inks deliver a bold pop of color that feels electric—ideal for designs that need to stand out in both daylight and nightlife environments. While they are not as opaque as standard plastisols, they perform best on white or light-colored garments to maximize brightness. For apparel brands seeking a vibrant, energetic, and youthful look, neon inks are the go-to choice.

Glow-in-the-dark ink is a specialty screen printing ink that absorbs light and then emits a luminous glow in dark settings. During the day, it appears as a subtle, slightly tinted print, but once the lights go out, the design comes to life with a bright, glowing effect. This makes it perfect for concerts, nightlife, promotional events, Halloween collections, and novelty designs.

Glow inks are typically printed as an underlayer or highlight on lighter garments to maximize brightness. They can be combined with other inks for hidden effects—appearing standard in daylight but glowing with a surprise reveal in darkness. Durable and long-lasting when properly cured, glow-in-the-dark ink delivers a unique, interactive decoration that adds fun and creativity to any apparel line.